- Catalogues

- COMI GROUP

- CENTRE D'USINAGE A CONTROLE NUMERIQUE

Extraits du catalogue

DRIVE YOUR TECHNOLOGY

Ouvrir le catalogue en page 1COMI Worldwide The Group COMI is established in August 1973 with the aim of designing and producing thermoforming machinery, specifically for the refrigeration sector. After 50 years of activity, today COMI is a solid industrial reality, with more than 3.500 systems installed in over 50 countries all around the world, a top-level reference list and a brand among the most prestigious in its market. When the significant development abroad consolidated the company as a reference player in the refrigeration sector, the management decided to diversify its range of solutions through the expansion...

Ouvrir le catalogue en page 2Facts & Figures among direct and indirect directs et indirects of Sales/des Ventes from international markets des marchés internationaux Proprietary/ Technologie technologies Brevetées Manufacturing/ Sites facilities in Italy de production en Italie Milion/Milions euro revenues de chiffre d’affaires en euros Invested/ Investis constantly in R&S in R&S Machines/des Machines installed globally installées dans le mo

Ouvrir le catalogue en page 3Household Appliances Appareils Èlectromènagers Automotive Automobile Hydro-sanitary Hydro-sanitaire Aerospace Aèronautique Marine Maritime Railway Ferroviaire

Ouvrir le catalogue en page 4“The strong know-how of TechMill division makes it the ideal partner la division “Le savoir-faire dede personnaliser TechMill permet TechMill is a division of COMI Group which offers a complete range of CNC machining centers for machining of a wide range of materials. Techmill est une division du groupe COMI qui offre une gamme complète de centres d’usinage CNC pour une large gamme de matériaux. when high customization is required. Labor milling centers range is dedicated to the machining of plastic materials, glass fiber, carbon fiber, composites, up to aluminum and light alloys. les...

Ouvrir le catalogue en page 5Best application / Application idéale Suggested application / Application suggérée INDUSTRIAL INDUSTRIELLE MOLD MODÈLES WIND EOLIENNE RAILWAY FERROVIAIRE MARINE NAUTIQUE AUTOMOTIVE AUTOMOTIVE AEROSPACE AÈROSPATIAL LIGHT ALLOYS ALLAGES LÈGÈRES ALUMINIUM ALUMINUM WOOD BOIS RESIN RÈSINES PLASTICS PLASTIQUE COMPOSITES COMPOSITIES

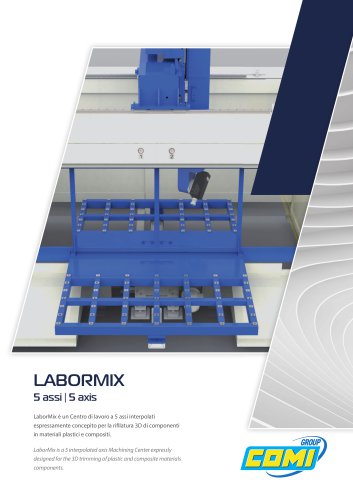

Ouvrir le catalogue en page 6LaborMix is a 5 interpolated axis milling center specifically designed for the machining of plastic and composite materials. LaborMix est un centre d’usinage 5 axes interpolés, spécialement conçu pour l’usinage de matériaux plastiques et composites. Equipped with working head with spindle at two opposite exits or four independent spindle head, it is the best solution for three-dimensional trimming of thermoformed parts. With working head with spindle and automatic toolchanger, it is instead widely used for the machining of small resin and wood models. Equipé d’une tête avec une broche à...

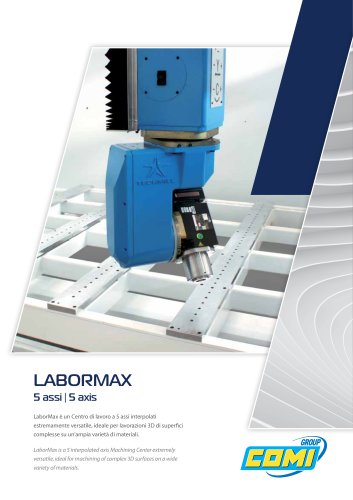

Ouvrir le catalogue en page 7LaborMax is an extremely versatile working center capable to satisfy the milling requirements on a wide variety of materials, with characteristics which made it the best solution for composite materials working operations. Labormax est un centre d’usinage extrêmement polyvalent capable de répondre aux exigences de fraisage sur une grande variété de matériaux, avec des caractéristiques qui en ont fait la solution idéale pour le traitement des matériaux composites. Available in several standard dimensions and versions, with fixed, rotary (pallet changer) or extractable tables, with different...

Ouvrir le catalogue en page 8LaborMac is a 5-axis machining center specifically developed to optimize the machining of molds and parts in aluminum and composite. The extreme rigidity provided by the monolithic structure with Gantry type mobile portal on the Y axis, significantly limits the vibrations helping to achieve very good quality even at high speeds. LaborMac version “C” offers instead high performance in modeling and trimming of composite materials and resins, can be equipped with Oil Mist and suction hood for dust extraction. The version “A“, dedicated to aluminum machining, is equipped with a working head of...

Ouvrir le catalogue en page 9LaborMidi has been specifically designed to machine aluminum, policarbonate and technical polymers. Its “open” configuration with mobile bridge allows a wide access from the 2 sides of the machine, but also allows to be used in totally automated production systems which require automatic loading/unloading by robotized devices. Available in the 3 and 5 axes version, it can be equipped with a wide range of accessories according to customer needs. LaborMidi is an effective solution for panel machining with a very good quality/price ratio, extremely easy to install and introduce in the...

Ouvrir le catalogue en page 10LaborShape is a 5 axis machining center specifically designed for high speed machining on aluminum and light alloys. LaborShape est un centre d’usinage conçu pour l’usinage à grande vitesse de moules et modèles en aluminium ou alliages légers. Compact dimensions and extremely rigid monolithic structure, axis displacement with recirculating ball screws and magnetic linear guides to ensure the best accuracy, working head with torque motors are the main technical features which makes this model the best solution for high chip removal. Dimensions compactes et structure monobloc extrêmement...

Ouvrir le catalogue en page 11LaborWind is the family of machining centers designed for those applications requiring the biggest working area, especially for the vertical “Z” axis. The mobile crossbeam, “suspended” on lateral steel or reinforced concrete structures, allows to cover very large working areas without overload the basic structure of the machine. Available with various spindle power and tool magazine configurations, with longer longitudinal axis strokes versions the machine can also be supplied with double mobile crossbeam and independent working unit, thus to double the production capacity. LaborWind is the...

Ouvrir le catalogue en page 12Tous les catalogues et fiches techniques (PDF) COMI GROUP

- THERMOFORMAGE

40 Pages

- WATERJET MACHINES

16 Pages

- Institutional Catalog

64 Pages

- PLASTICS INJECTION MACHINE

8 Pages

- Milling Turning Grinding

12 Pages

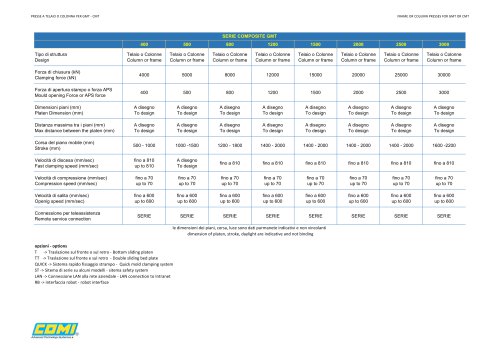

- Composite GMT Series

1 Page

- SERIE COMPOSITE SMC

1 Page

- Machine de coupe

- Presse industrielle

- Machine de coupe pour métal

- Machine d'usinage

- Machine de coupe CNC

- Machine d'usinage verticale

- Système de découpe laser

- Presse hydraulique

- Presse de formage

- Machine de découpe pour applications industrielles

- Machine de coupe automatique

- Machine de tournage CNC

- Rectifieuse industriel

- Centre d'usinage à 3 axes

- Système de découpe à lame

- Machine de découpe haute précision

- Machine de découpe de tôle

- Armoire de stockage

- Machine de coupe à grande vitesse

- Machine de fabrication