- Catalogues

- COMI GROUP

- THERMOFORMAGE

Extraits du catalogue

DRIVE YOUR TECHNOLOGY

Ouvrir le catalogue en page 1COMI Worldwide The Group COMI is established in August 1973 with the aim of designing and producing thermoforming machinery, specifically for the refrigeration sector. After 50 years of activity, today COMI is a solid industrial reality, with more than 3.500 systems installed in over 50 countries all around the world, a top-level reference list and a brand among the most prestigious in its market. When the significant development abroad consolidated the company as a reference player in the refrigeration sector, the management decided to diversify its range of solutions through the expansion...

Ouvrir le catalogue en page 2Facts & Figures among direct and indirect directs et indirects of Sales/des Ventes from international markets des marchés internationaux Proprietary/ Technologie technologies Brevetées Manufacturing/ Sites facilities in Italy de production en Italie Milion/Milions euro revenues de chiffre d’affaires en euros Invested/ Investis constantly in R&S in R&S Machines/des Machines installed globally installées dans le mo

Ouvrir le catalogue en page 3Household Appliances Appareils ménagers Automotive Automotive Hydro-sanitary Hydro-sanitaire Aerospace Aerospace Marine Maritime Railway Ferroviaire

Ouvrir le catalogue en page 4THERMOFORMING SOLUTIONS

Ouvrir le catalogue en page 5AMUT-COMI has been created by merging AMUT Thermoforming Division and COMI division for packaging thermoforming machines. AMUT S.p.A. is a historical Italian company specialised in plastics processing plants and foil thermoforming machines. COMI S.p.A. has been active since the 1970s as a leading company in the production of thermoforming machines for the white goods industry and for the packaging industry following the acquisition of the Italian CBM Moretti. AMUT-COMI is the union of technological and innovation know-how for the thermoforming of items for packaging. AMUT-COMI est née de la...

Ouvrir le catalogue en page 6EASY is the software that understands the data set by the operator and processes them proposing optimized solutions. EASY est le logiciel qui analyse les données fournies par l’opérateur et les traite pour proposer des solutions optimisées. • Automatic adjustment of the parameters of the cycle based on the set speed. • Optimized diagnostic with information for research and fully independent solution of the problems. • Monitor displaying of I/O PLC cards. • Automatic check of the set parameters refusing data that are not compatible with the predefined cycle. • Detailed pie chart of all...

Ouvrir le catalogue en page 7ACF SERIES /FORMING & CUTTING SERIE ACF /PRESSE ET DECOUPE Machines suitable for the production of trays, plates, lids, containers, flowerpots in thermoplastic material, such as BOPS, PP, PLA, rPET, APET, CPET, HIPS, EPS, PVC and barrier. High flexibility and advanced technology for small and large outputs, with cost-effective moulds. Machines adaptées à la production de plateaux, assiettes, couvercles, conteneurs et pots en matériaux thermoplastiques tels que BOPS, PP, PLA, rPET, APET, CPET, HIPS, EPS, PVC et matériaux barrières. Une grande flexibilité et une technologie avancée pour les...

Ouvrir le catalogue en page 8AMP SERIES /IN-MOULD FORMING & SERIE AMP /FORMAGE DANS LE MOULE ET Machines suitable for processing products in HIPS, PP, A-PET, R-PET, PLA and barrier material that require very high quality and dimensional accuracy. GPPS with in-line thermoforming process. These machines are therefore properly suitable to deliver containers and cups intended to be used in vending machines, filling and packaging lines. The AMP series is equipped with tilting lower mould. Machines adaptées à la production d’articles en HIPS, PP, A-PET, R-PET, PLA et matériaux barrières qui exigent une très haute qualité, un...

Ouvrir le catalogue en page 9FTV SERIES /IN-MOULD FORMING & TRIMMING Machines suitable for processing products in HIPS, PP, A-PET, R-PET, PLA and barrier material that require very high quality and dimensional accuracy. GPPS with in-line thermoforming process. These machines are therefore properly suitable to deliver containers, trays and cups intended to be used in vending machines, filling and packaging lines. The FTV series is equipped with verticalmovement lower mould. SERIE FTV /FORMAGE DANS LE MOULE ET PRESSE Machines adaptées à la production d’articles en HIPS, PP, A-PET, R-PET, PLA et matériaux barrières qui...

Ouvrir le catalogue en page 10PA 1000 / IN-MOULD FORMING & TRIMMING PA980Q-VP / IN-MOULD FORMING & CUTTING High capacity machines for the production of plates, trays and shallow products. Two configurations are available: PA1000 Forming and trimming in the same station and integrated stacking in the lower part of the mould. Suitable for HIPS articles, because of vacuum forming. PA980Q-VP Forming and steel rule cutting in the same station and stacking station. Suitable for articles in PP, HIPS, A-PET, R-PET, PLA and barrier materials, because of vacuum and air pressure forming. PA 1000 / FORMAGE DANS LE MOULE ET PRESSE...

Ouvrir le catalogue en page 11GLE SERIES /FORMING & SEPARATE TRIMMING Machines properly designed for the production of HIPS disposable and vending cups. Forming with vertical-movement mould and trimming with horizontally driven press machine. In-line configuration with feeding of the foil directly from the extruder head to the forming station. Energy saving technology based on the absence of heating panels. SERIE GLE /FORMAGE ET PRESSE SEPAREE Machines dédiées à la production de gobelets jetables en HIPS et à la distribution automatique. Le formage avec une matrice à déplacement vertical et le découpage avec une presse...

Ouvrir le catalogue en page 12IN-LINE SYSTEMS AND TURN-KEY PROJECTS AMUT-COMI together with AMUT supply complete in-line thermoforming plants. Advantages: • Low energy consumption (the plastic material requires less energy to reach the thermoforming temperature) • Instant control of the film quality and, consequently, of the finished article • Closed loop processing of the thermoforming skeleton • Constant quality control even after changing some extrusion and thermoforming parameters • Best performances in thermoforming machine speed Auxiliary equipment: • Rimming machines for PP or HIPS cups • Stacking unit for...

Ouvrir le catalogue en page 13Tous les catalogues et fiches techniques (PDF) COMI GROUP

- WATERJET MACHINES

16 Pages

- Institutional Catalog

64 Pages

- PLASTICS INJECTION MACHINE

8 Pages

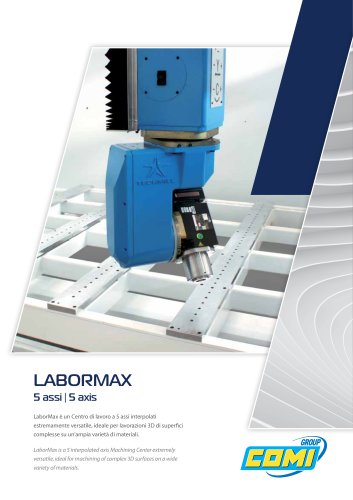

- Milling Turning Grinding

12 Pages

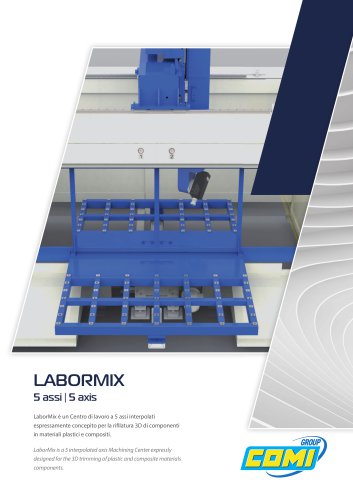

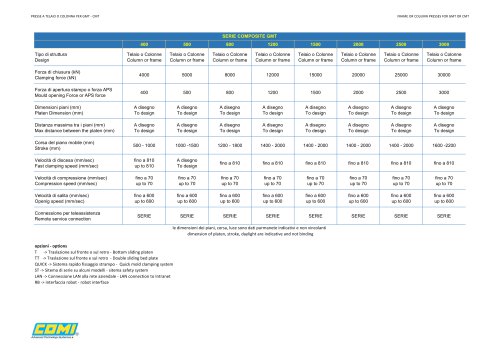

- Composite GMT Series

1 Page

- SERIE COMPOSITE SMC

1 Page

- Machine de coupe

- Presse industrielle

- Machine de coupe pour métal

- Machine d'usinage

- Machine de coupe CNC

- Machine d'usinage verticale

- Système de découpe laser

- Presse hydraulique

- Presse de formage

- Machine de découpe pour applications industrielles

- Machine de coupe automatique

- Machine de tournage CNC

- Rectifieuse industriel

- Centre d'usinage à 3 axes

- Système de découpe à lame

- Machine de découpe haute précision

- Machine de découpe de tôle

- Armoire de stockage

- Machine de coupe à grande vitesse

- Machine de fabrication