Extraits du catalogue

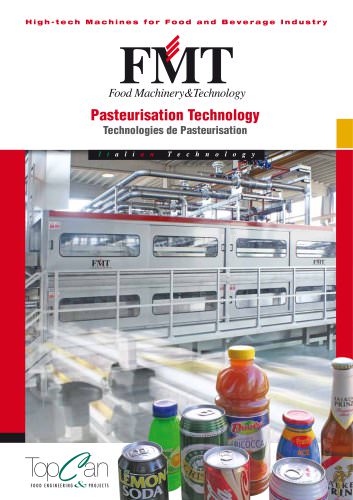

High-tech Machines for Food and Beverage Industry Food Machinery&Technology Pasteurisation Technology FOOD ENGINEERING OC PROJECTS

Ouvrir le catalogue en page 1

High-tech Machines for Food and Beverage Industry FMT Brand Marque FMT The FMT company, with over a hundred pasteurisers installed all over the world, is recognized as a leading company of the sector. The production and the sales of the wide range of models makes of FMT product range one of the most complete currently available on the market. The easy functioning and maintenance as well as the quality of the treatment made, make of FMT pasteurisers an ideal solution to carry out pasteurizing, heating and cooling cycles on glass and plastic bottles and cans. All formats can be treated and...

Ouvrir le catalogue en page 2

Food Machinery&Technology Process Control The control and the adjustment of all the process parameters are possible through the industrial PC installed on the operator control board. The dynamic diagram allows the monitoring of the heat treatment phases and shows real time the pasteurising details of the product coming out. The mimic diagram shows the conditions of the pasteuriser functional devices (pumps, valves, etc.) and can also permit the reading of the steam and water consumption. All functional details of the pasteuriser are automatically recorded on files so that further...

Ouvrir le catalogue en page 3

High-tech Machines for Food and Beverage Industry Automatic control system of Pasteurising Units Système automatique des Unites de Pasteurisation PRODUCT QUALITY WITH ACSPU The FMT Company developed with its own pasteurisers a control system called ACSPU. The system satisfies the more and more demanding requests of the customers in terms of heat treatment quality of the products and in terms of energy savings. Traditionally the accuracy of the heat treatment is measured through the number of UP (pasteurising units) loaded by the product Our system is based on the premise that the product...

Ouvrir le catalogue en page 4

Food Machinery&Technology Thermic Cycle FMT is not only characterized by the careful attention given to the manufacture of the mechanical parts but also to the special care that is paid to the quality of the heat treatment. Bottles and cans samples supplied by our customers are tested c/o our laboratories in order to test the exact heat exchange coefficient. The testing equipment permits in fact the realization of a complete thermic treatment of the packed products. The process parameters are controlled by a computer that records them and then uses them in the elaboration of thermic...

Ouvrir le catalogue en page 5

High-tech Machines for Food and Beverage Industry

Ouvrir le catalogue en page 6

PASTEURISATION TECHNOLOGY Food Machinery&Technology

Ouvrir le catalogue en page 7

High-tech Machines for Food and Beverage Industry Main Conveyor Convoyeur principal The modular mat conveyor system permits a considerable steadiness of the product (both for bottles and cans) making the functioning extremely simple and reducing considerably the maintenance operations. The product handling is made on one or two levels (decks) placed inside the tunnel divided in two parts. Each mat is controlled by an independent gearmotor – the system becomes therefore extremely versatile and grants the possibility to make partial production if required, by simply arresting one of the mat....

Ouvrir le catalogue en page 8

Food Machinery&Technology Modular configuration Our pasteurisers can be composed of one or two tunnels matched on a same deck or on two decks. The structure – entirely made in stainless steel – is composed of modular elements with variable length and reaching a max. 7 meters width. The total length of the tunnel can vary from 8 up to 40 meters. Many different requests from our customers can be satisfied especially in terms of productivity and room availability. The access to the internal part of the tunnel is made easier through lateral double doors – on each side of the tunnel and on each...

Ouvrir le catalogue en page 9

High-tech Machines for Food and Beverage Industry Dynamic Transfer Trasferimento Dinamico The dynamic transfer of the products from the conveyors to the pasteuriser/cooler/heater mat (and vice versa) is for FMT an already well established achievement used for many projects. The system is available both for glass containers and for cans. It can be installed both at the entry and at the exit of the pasteuriser (thus avoiding the stoppage of containers on passage plates at the production end). The system – if used on hot filling lines – prevents the bottles from being stopped on fixed...

Ouvrir le catalogue en page 10

FOOD ENGINEERING <5*3 PROJECTS Food Machinery&Technology Product Heating COOLER TEMPERATURE PROCESS DATA -WATER TEMPERATURE -PRODUCT TEMPERATURE TIME (minutes] The wide range of product that FMT can supply, includes containers cooling or heating Systems - respectively for hot filling lines or f or cold filling lines or for ambient température filling lines. The heat treatment is adapted to each type of product being processed, even though the constructive main features of the différent models remains the same. Spécial solutions can be adopted to save consumptions (especially water) in case...

Ouvrir le catalogue en page 11

High-tech Machines for Food and Beverage Industry global solutions meant to the best technological partner capable to engineer, realize globales pour l'automatisation diverses exigences du marché pour l'Industrie des conserves FOOD ENGINEERING <SsZ PROJECTS Food Machinery&Technology Strada Cisa, 111 - 43045 Ricco (PARMA) Italy Sales department 43044 Lemignano di Collecchio (Parma) Italy sales@fmt.it - www.fmt.it

Ouvrir le catalogue en page 12Tous les catalogues et fiches techniques (PDF) FMT

-

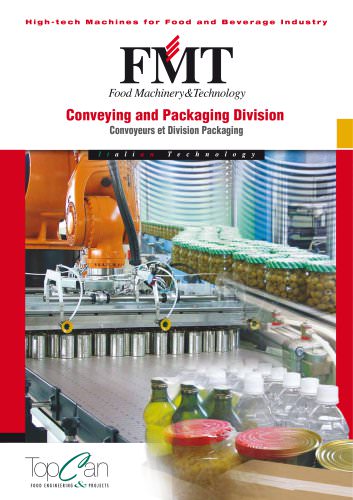

Convoyeurs et Division Packaging

16 Pages