Extraits du catalogue

MOTION & CONTROL™

Ouvrir le catalogue en page 1

As one of the world's leading manufacturers of rolling bearings, linear technology components and steering Systems, we can be found on almost every continent - with production facilities, sales offices and technology centres - because our customers appreciate short decision-making channels, prompt deliveries and local service. NSK commenced opérations as the first Japanese manufacturer of rolling bearings back in 1916. Ever since, we have been continuously expanding and improving not only our product portfolio but also our range of services forvarious industrial sectors. In this context, we...

Ouvrir le catalogue en page 2

Partnership based on trust – and trust based on quality Total Quality by NSK: The synergies of our global network of NSK Technology Centres. Just one example of how we meet our requirements for high quality. NSK is one of the leading companies with a long tradition in patent applications for machine parts. In our worldwide research centres, we not only concentrate on the development of new technologies, but also on the continual improvement of quality based on the integrated technology platform of tribology, material technology, analysis and mechatronics. More about NSK at www.nskeurope.com...

Ouvrir le catalogue en page 3

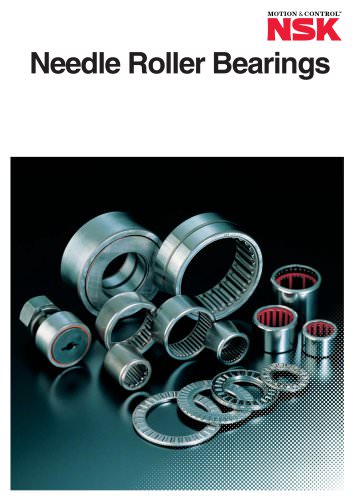

Introduction When a rolling bearing is damaged during machine operation, the entire machine or equipmentmay seize or malfunction. Since bearings that fail prematurely or unexpectedly cause trouble, it is important to be able to identify and predict failure beforehand, if possible, so that preventive measures can be adopted. Generally, bearing inspection or housing inspection can identify the cause of the problem. Often the cause is attributable to poor lubrication, improper handling, selecting the wrong bearing, or not enough study of the shaft and housing. Usually the cause can be...

Ouvrir le catalogue en page 6

Bearing Handling & Maintenance Precautions for Handling Since rolling bearings are high precision machine parts, they must be handled carefully. Even if high quality bearings are used, their expected life and performance cannot be attained if they are used improperly. The main precautions to be observed are as follows: (1) Keep the bearings and surroundings clean: Dust and dirt, even if invisible to the naked eye, have harmful efects on bearings. It is necessary to prevent f the entry of dust and dirt by keeping the bearings and their environment as clean as possible. (2) Handle with care:...

Ouvrir le catalogue en page 7

Bearing Handling & Maintenance Mounting It is advisable to study the bearing mounting thoroughly since the quality of the bearing mounting influences the bearing’s running accuracy, life and performance. It is recommended that the mounting method includes the following steps. ›› Clean the bearing and surrounding parts. ›› heck the dimensions and finish conditions of C related parts. ›› Follow mounting procedure. ›› Check if the bearing is mounted correctly. ›› Supply with correct kind and quantity of lubricant. It is necessary to periodically inspect and maintain the bearing and its...

Ouvrir le catalogue en page 8

Table 1 Methods to check operation Machine size Operating procedure Bearing condition checks Manual operation. Turn the bearing by hand. If no problems are detected, then proceed to operate the machine. ››Stick-slip (Debris, cracks, dents) ››Uneven rotating torque (Faulty mounting) ›› xcessive torque E Power operation. Initially start at a low speed and without a load. Gradually increase speed and load to reach rating. Check for irregular noise. Check for bearing temperature rise. Lubricant leakage. Discoloration. Idle operation. Turn ON power and allow machine to rotate slowly. Turn OFF...

Ouvrir le catalogue en page 9

Bearing Performance Factors Key bearing performance factors during operation are bearing noise, vibration, temperature, and lubricant state. Please refer to Table 2 if any operation irregularities are detected. Bearing Noise During operation, sound detection instruments (stethoscope, NSK Bearing Monitor, etc.) can be used to investigate the volume and characteristics of the bearing rotation noise. It is possible to distinguish bearing damage such as small flaking by means of its unusual yet characteristic noise. Bearing Vibration Bearing irregularities can be analyzed by measuring the...

Ouvrir le catalogue en page 10

Table 3 Comparison between grease and oil lubrication Table 4 Required viscosity by bearing type Fig. 1 Relation between oil viscosity and température Bearing lubrication methods are divided into two main catégories: grease lubrication and oil lubrication. A lubrication method is adopted that matches the application conditions and application purpose in order to attain best performance from the bearing. Table 3 shows a comparison between grease and oil Grease is a lubricant that is made from base oil, thickener, and additives. When selecting a grease, it is necessary to select a grease that...

Ouvrir le catalogue en page 11

Bearing Performance Factors Replenishment and Replacement of Lubricant (1) Replenishing Interval Even if high-quality grease is used, there is deterioration of its properties with time; therefore, periodic replenishment is required. Figs. 2 (1) and (2) show the replenishment time intervals for various bearing types running at different speeds. Figs. 2 (1) and (2) apply for the condition of high-quality lithium soap-mineral oil grease, bearing temperature of 70° C, and normal load (P/C=0.1). ›› emperature T If the bearing temperature exceeds 70° C, the replenishment time interval must be...

Ouvrir le catalogue en page 12

Table 6 Sélection of lubricating oils for différent bearing applications Notes: 1. As for the limiting speed, use the value listed under oil lubrication in the Bearing Dimension Tables of "NSK Rolling Bearings" (No. E1102). 2. Refer to refrigerator oil (JIS K 2211), Bearing oil OIS K 2239), Turbine oil OIS K 2213), Gear oil OIS K 2219). 3. Température ranges are shown in the left column in the table above. For operating températures that are on the high température side, a high viscosity lubrication oil is recommended. Fig. 2 Grease replenishment intervais (1) Radial bail bearing and...

Ouvrir le catalogue en page 13Tous les catalogues et fiches techniques (PDF) NSK Europe Ltd.

-

Ball Screws - BSS Series

1 Pages

-

Creep-Free Bearings Series

1 Pages

-

BNEQARTET Bearings

1 Pages

-

TF Series Bearings

1 Pages

-

HMS series

1 Pages

Catalogues archivés

-

Bearing Replacement Guide

264 Pages

-

Paliers Self-Lube

158 Pages

-

ROULEMENTS

473 Pages

-

Le PRECISION EN MOUVEMENT

13 Pages

-

Guide de Maintenance

45 Pages

-

Agri Disc Hub

1 Pages

-

ROBOT MODULE™ MR SERIES

44 Pages

-

Precision Machine Components

55 Pages

-

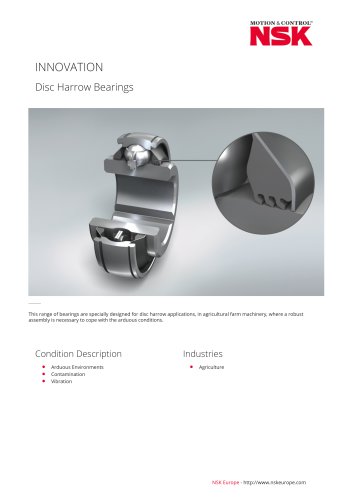

Disc Harrow Bearings

2 Pages

-

ROLLING BEARINGS

707 Pages

-

TECHNICAL INSIGHT

2 Pages

-

Hub unit bearings

23 Pages

-

CONDITION MONITORING

6 Pages

-

BEARING MOUNTING TOOLS

28 Pages

-

Automotive Products

48 Pages

-

NSK IN EUROPE

6 Pages

-

Linear Guides Standard Items

62 Pages

-

Bearings for the Steel Industry

44 Pages

-

Bearings for the Cement Industry

20 Pages

-

Authorised Distributor

7 Pages

-

Added Value Training

12 Pages

-

Handling Instructions

48 Pages

-

Pocket Guide Linear Motion

44 Pages

-

Molded Oil™- Bearings

9 Pages

-

Plummer Blocks

52 Pages

-

Double Row Ball Bearing

44 Pages

-

Corporate Precision Components

24 Pages

-

Troubleshooting poster

1 Pages

-

Guide to RHP Self-Lube

12 Pages

-

Super Precision Bearings

120 Pages

-

Ball Screw Support Bearings

44 Pages

-

Deep Groove Ball Bearings

12 Pages

-

Asset improvement programme

6 Pages

-

Bearings for Pumps & Compressors

24 Pages