- Catalogues

- PUTZMEISTER

- BP 4678

- Société

- Produits

- Catalogues

- News & Trends

- Salons

Extraits du catalogue

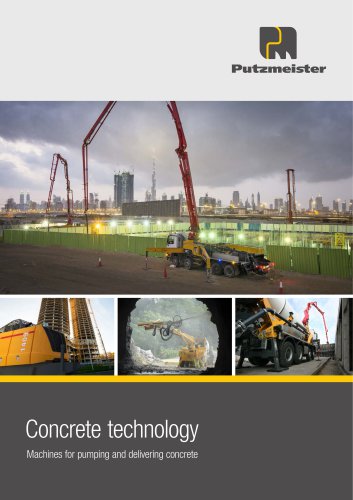

Leading technology for profitable business - worldwide Welcome to one of the leading providers of solutions for pumping, mixing and transporting concrete. Our first-class products are setting the standard in the industry, especially in terms of sustained and profitable growth for our customers, because ultimately we develop technology that extends beyond conventional ways of thinking and find solutions beyond the capabilities of others that stand out from the competition in every respect.

Ouvrir le catalogue en page 2Stationary concrète pumps Pages 10-13 Truck mixer concrète pumps Pages 14-15 Shotcrete and tunnel concrète pumps Pages 16-17 Truck mixers Pages 18-19 Telebelt mobile belt conveyors Largest continuous concreting operation, recognised by the Guinness Book of Records (image left) In February 2014, Putzmeister truck-moun-ted concrete pumps poured 16200 m3 of concrete for the foundation slab of the New Wilshire Grand Center in Los Angeles, USA.

Ouvrir le catalogue en page 3Delivering success for your company How do we do it? We ask the right questions and find the best possible answers so that we can work together constructively as a team to develop tailored solutions that meet the needs of our customers. Our customer and future-oriented employees are conscious of the fact that our machines will need to perform a number of important tasks – your tasks. Proximity to the customer helps optimise practical technology Putzmeister’s basic philosophy is to develop products that make structural, underground and civil engineering easier, more economical and more...

Ouvrir le catalogue en page 4Quality standards offer security Innovations must be proven in practice and they therefore undergo a series of endurance tests so that you can place your full trust in quality “made by Putzmeister” in harsh everyday operations on the construction site: ■■ L ifetime simulations for placing booms ■■ W ear tests for delivery lines, spectacle wear plates, etc. P ulse tests and burst pressure tests for delivery and hydraulic hoses C limate, temperature and spray water tests for all machines and their components C omprehensive field tests for the entire machine Outstanding customer care all over...

Ouvrir le catalogue en page 5We can provide first-class placing booms with a vertical reach of around 20 to 63 m for all your projects. The optimised fold system, compact dimensions of the vehi-cle, low-wearing materials and excellent processing capabilities ensure that your machine is well equipped for the most de-manding requirements in the long term. system height reach depth system height reach depth * With end hose elbow

Ouvrir le catalogue en page 6City pumps Max. output Placing boom – user-friendly, low-wearing Operation 2.0 The Ergonic ® 2.0 radio remote control offers practical extended functions and maximum operating comfort with clearly laid out displays and setting options as well as our established fault management system. Our booms offer advantages in every direction ■■ D ifferent horizontal reaches and fold systems for greater flexibility and versatility M inimal to no dead space L ow-wear, low-maintenance components Good accessibility D irect response characteristics of boom control Comfortable handling A uxiliary EBC...

Ouvrir le catalogue en page 7Support system – flexible, space-saving, safe Construction sites often only offer restricted set-up conditions because they are located in urban areas or along busy roads. The use of truck-mounted concrete pumps essentially depends on the support dimensions. Assistance system OSS* (One Side Support) ■■ U sed successfully since bauma 1995 E xtended options – through flexible support, high machine capacity utilisation and extended working areas The base structure provides optimised force distribution that does not damage the vehicle B oom can be utilised fully in restricted working areas S...

Ouvrir le catalogue en page 8The pump – efficient, smooth-running, wear-resistant Piston pumps with free-flow hydraulics In a closed circuit, the oil goes from the pump to the drive cylinder with minimal losses. For more efficiency and significantly less oil consumption. EPS (Ergonic ® Pump System) EPS regulates operation of the concrete pump, engine and placing boom fully electronically. ■■ H igh-quality low-wearing components guarantee a high degree of machine availability M inimal noise during the optimised pumping process V ibrations in the machine and boom are reduced EOC (Ergonic ® Output Control) Engine operates...

Ouvrir le catalogue en page 9No two jobs are the same. Requirements such as the delivery rate, delivery range, special ambient conditions and concrete quality must be calculated for each indivi-dual site. We manufacture perfectly engi-neered pumps in all performance and price categories. * Available with engine emission Stage IV or US EPA Tier 4 final

Ouvrir le catalogue en page 10Swing doors provide easy access and protection from the weather Good access for service work Mini measuring panel: hydraulic measuring points read from a central point Clearly laid out EGD (Ergonic® Graphie Display) Advantages in terms of operation, cleaning and maintenance ■ The position of hydraulics and changeover cylinder outside the concreting area prevents pollution ■ External gate valve connection (series from stroke of 1 400 mm) ■ Easy to change all components on the S tube ■ Rapid piston replacement thanks to water box with open top, easy access to water drain cock and automatic...

Ouvrir le catalogue en page 11The MX system - perfect ratio between set-up time and performance The comprehensive, modular range of MX stationary booms makes different horizontal reaches available on the Putzmeister tubular column system RS-850 or lattice towers from well-known manufacturers. Arms which can be moved from the truck-mounted con-crete pump to the tubular column and from there to the next tubular column in minimal time thanks to the rapid disconnection systems not only provide massive scope in the height, but also in the area. A ballast is not required up to a horizontal reach of 36 m despite a maximum...

Ouvrir le catalogue en page 12MX stationary booms ■ With or without counterweight* ■ Comfortable transport and set-up and minimal set-up times thanks to rapid disconnection devices ■ Secure handling ■ Many set-up and attachment variants on the base plate, at the structure or on a climbing formwork adapt to each construction site situation ■ Automatic climbing process with hy-draulic climbing device allows the boom to grow with the structure ■ Minimal space requirement ■ Remote control via cable or radio ensures precise, comfortable working ■ Simple, 1 m2 square ceiling recess is sufficient for the access passage ■...

Ouvrir le catalogue en page 13Tous les catalogues et fiches techniques (PDF) PUTZMEISTER

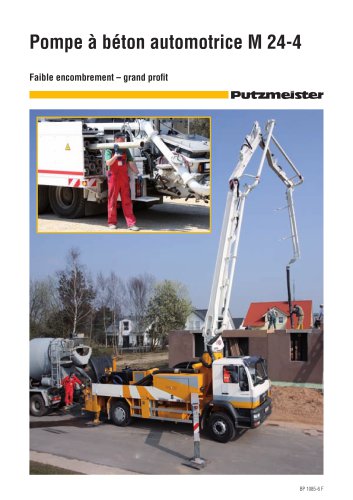

- Pompe à béton automotrice 20-4

12 Pages

- Pompe à béton automotrice 38-5

12 Pages

- Pompe à béton automotrice 36-4

12 Pages

- Systèmes de tuyauterie

13 Pages

- Catalogue 2018/2019

74 Pages

- Mâts stationnaires MX

11 Pages

- Des solutions économiques

21 Pages

- Pompes à béton stationnaires

15 Pages

- Malaxeurs-pompes PUMI®

28 Pages

- Pompes à béton automotrices

17 Pages

- BP_1700

32 Pages

- MM 4574

62 Pages

- BP_2059

20 Pages

- BP 2047

28 Pages

- BP_2632

28 Pages

- Pompe à béton RoLine

2 Pages

- Delivery line systems

24 Pages

- Pompe industriel

- Pompe industrielle

- Pompe entraînée par moteur

- Pompe pour eau de mer

- Convoyeur

- Cuve industriel

- Convoyeur de transport

- Convoyeur à bande

- Réservoir de stockage

- Convoyeur horizontal

- Pompe de refoulement

- Pompe renforcée

- Machine de fabrication additive

- Pompe 400V

- Pompe à vis

- Pompe pour le nettoyage

- Pompe en plastique

- Pompe réglable

- Pompe de remplissage

- Pompe silencieuse