- Catalogues

- Saimex Srl

- Caillebotis Composite

- Produits

- Catalogues

- News & Trends

- Salons

Extraits du catalogue

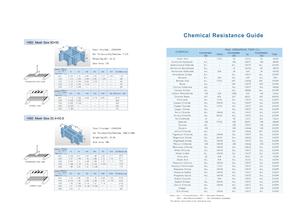

s 9 I j Mesh -> How to select grating When selecting grating, we suggest you to consider the following: * Environment « Loading « Impact We have to consider the environment including corrosion level, temprature etc, in which grating is going to be applied. Then we can choose the right resin System for the product. We also have to look at the load requirement at diffrent span. j Diff驩rent resin System available: * Ortho / PFR: Flame spread = 20 * ISO / IFR: flame spread = 15 sr Vinyl ester: Flame spread = I 5 * High Fire Retardand IFR: flame spread = 10 « High Fire Retardand VFR: flame spread = 10 « Phenolic: Flame spread = 0 « Food grade & Translucent Square mesh Rectangular Mesh Mini Mesh j Surface Concave top Gr/t top Smooth top j Covered grating Smooth top Grit top Patterned top j Color availble Standard stock color: Custom color is available upon request

Ouvrir le catalogue en page 1FRP Molded Grating Molded Grating Process Molded grating is manufactured by laying continuous glass fibers in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layers by layers. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary opration. This continuous process produces an intgral, one-piece panel, which offers excellent corrosion...

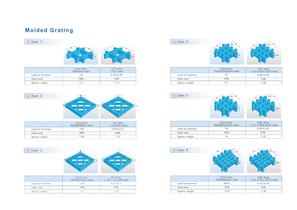

Ouvrir le catalogue en page 2Molded Grating 1 4mm thick, 40x40(20x20)mm mesh 0.55" thick, I.6"xl.6"(0.8"x0.8") mesh Load bar thickness 7/5 0.2870.20" Open area 42% 42% Approx. weight 9.3 1.90 13mm thick, 50x50(DM)mm mesh 1/2" thick, 2"x2"(DM) mesh Load bar thickness 10/9 0.4070.35" Open area 68% 68% Approx. weight 7.46 1.53 22mm thick, 40x40(20x20)mm mesh 0.86" thick, I.6"xl.6"(0.8"x0.8") mesh Load bar thickness 7/5 0.2870.20" Open area 42% 42% Approx. weight 16 3.28 13mm thick, 1/2" thick, 38x38(DM)mm mesh 1 l/2"xl 1/2" (DM) mesh Load bar thickness 5.8/5 0.2370.2" Open area 78% 78% Approx. weight 6 1.23 22mm thick,...

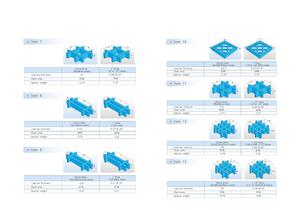

Ouvrir le catalogue en page 4* lt 25mm thick, 38x38(DM)mm mesh 1 " thick, 1 l/2"xl 1/2" (DM) mesh Load bar thickness 6/4.5 0.2470.19" Open area 68% 68% Approx. weight 14.38 2.94 25mm thick, 38x38mm mesh 1 " thick, 1 l/2"xl 1/2" mesh Load bar thickness 7/5 0.2870.20" Open area 70% 70% Approx. weight 12.59 2.58 I * Item 11 [ * Item 8 30mm thick, 38x38mm mesh I I/5" thick, I l/2"xl I/2" mesh Load bar thickness 7/5 0.2870.20" Open area 68% 6896 Approx. weight 15.90 3.07 25mm thick, 1 " thick, 25x 100mm mesh 1 "x4" mesh Load bar thickness 9.5/5 0.3770.20" Open area 68% 68% Approx. weight 13.05 2.67 * Item 9 30mm thick,...

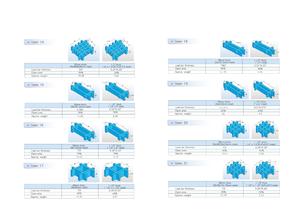

Ouvrir le catalogue en page 530mm thick, 1.2" thick, 40x40(8x8)mm mesh 1.6" x I.6"(0.3"x0.3") mesh Load bar thickness 6/5 0.2470.20" Open area 36% 36% Approx. weight 19.58 4.01 38mm thick, 25x 101.6mm mesh I I/2" thick. I " x 4" mesh Load bar thickness I3&5 0.5270.20" Open area 46% 46% Approx. weight 21.70 4.45 * Item 15 l * Item 19 38mm thick, 25x I 52mm mesh I I/2" thick, I " x 6" mesh Load bar thickness I 2.7/9.5 0.570.375" Open area 63% 63% Approx. weight 22 4.5 38mm thick. 38x 101.6mm mesh I I/2" thick, I I/2" x 4" mesh Load bar thickness 6.5&5 0.2670.20" Open area 76% 76% Approx. weight I I.65 2.39 38mm thick,...

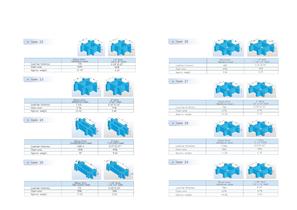

Ouvrir le catalogue en page 6* Item 22 * Item 26 40mm thick, 40x40mm mesh 1.6" thick, 1.6"x 1.6" mesh Load bar thickness 7/5 0.2870.20" Open area 66% 66% Approx. weight 21.43 4.39 20mm thick, 1 1/2" thick, 38x38mm mesh 1 1 /2" x 4" mesh Load bar thickness 6&5 0.2670.20" Open area 65% 76% Approx. weight 9.80 2.39 * Item 23 * Item 27 50mm thick, 50x50mm mesh 2" thick, 2"x2" mesh Load bar thickness 7.5/5 0.3070.20" Open area 71% 71% Approx. weight 23.43 4.80 25mm thick, 40x40mm mesh 1 " thick, 1.6" x 1.6" mesh Load bar thickness 7&5 0.2870.20" Open area 67% 67% Approx. weight 1 2.30 2.47 * Item 24 * Item 28 50mm thick,...

Ouvrir le catalogue en page 7* Item 30 *H25 Mesh Size 38x38 38mm thick, 25x 1 52mm mesh 1 1/2" thick, 1 " x 6" mesh Load bar thickness 7/5 0.2870.20" Open area 62% 62% Approx. weight 23.10 4.63 l * Item 31 40mm thick, 40x40-20x20mm mesh 1.57" thick, I.57" x 1.57" (0.8"x0.8")mesh Load bar thickness 7&5 0.2870.20" Open area 42% 42% Approx. weight 23./g 4.85 * Item 32 40mm thick, 50x50mm mesh 1.57" thick, 2" x 2" mesh Load bar thickness 6.8&5 0.2770.20" Open area 80% 80% Approx. weight 15.82 3.I7 * Item 33 60mm thick, 2.36" thick, 38x38mm mesh I-I/2" x I-I/2" mesh Load bar Ihk kness I 1,5&9 0.4570.35" Open area 54% 54%...

Ouvrir le catalogue en page 8Chemical Rsistance Guide CHEMICAL Concentration Ortho Concentration Concentration Vinyl (%) m Iso {%) Acetic Acid 7 77/25 50 125/52 50 180/82 Aluminum Hydroxide ALL 100 160/71 100 180/82 Ammononium Chloride ALL ALL 170/77 ALL 210/99 Ammonium Bicarbonate ALL 15 125/52 50 160/70 Ammonium Hydroxide ALL N/R 28 N/R 28 100/38 Ammomium Sulfate ALL ALL 170/77 ALL 2 10/99 Benzne ALL N/R ALL N/R ALL N/R Benzoic Acid ALL 77/25 SAT 150/66 SAT 21 0/99 Borax ALL SAT 170/77 SAT 210/99 Calcium Carbonate ALL ALL 170/77 ALL 180/82 Calcium Nitrate ALL ALL 180/82 ALL 210/99 Carbon Tetrachloride 100 N/R 1000...

Ouvrir le catalogue en page 10Molded Grating Application

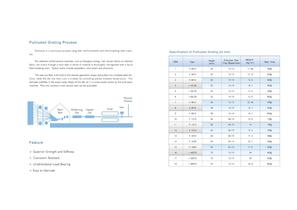

Ouvrir le catalogue en page 11Pultruded Grating Process Pultrusion is a continuous process using fiber reinforcements with thermosetting resin matri- Spcification of Pultruded Grating (in mm) Pre-selected reinforcement materials, such as fiberglass roving, mat, woven fabrics or stitched fabric, are drawn through a resin bath in which ail material is thoroughly impregnated with a liquid thermosetting resin. Typical resins include polyesters, vinyl esters and phenolics. The wet-out fiber is formed to the desired gom驩trie shape and pulled into a heated steel die. Once inside the die, the resin cure is initiated by...

Ouvrir le catalogue en page 12Tous les catalogues et fiches techniques (PDF) Saimex Srl

- Floor resin wood

4 Pages

- Resin Sheet Piles

2 Pages

- DECK system hd

2 Pages

- Profilé industriel

- Profilé en métal

- Profilé de construction

- Profilé en plastique

- Fibre en verre

- Profilé en acier

- Profilé carré

- Profilé pultrudé

- Caillebotis en plastique

- Profilé en composite

- Profilé en H

- Fibre de verre

- Profilé spéciale

- Caillebotis en composite

- Profilé en matériaux composites

- Caillebotis en polyester

- Fibre en plastique